Precision in Every Print: Custom DTF Transfers by Size

When managing a custom apparel brand, efficiency and accuracy are the pillars of success. Ordering custom DTF transfers by size is the most strategic way to ensure your designs fit perfectly on every garment. In 2026, the industry has moved toward tailored dimensions for specific applications.

Whether you are printing a tiny neck label or a massive back design, choosing the right size is critical for aesthetic balance. This guide will walk you through the importance of sizing and how to optimize your orders for maximum impact and cost-effectiveness. Precision in sizing reflects the quality and care you put into your brand.

Why Sizing Matters in Custom DTF Transfers

The visual appeal of a custom t-shirt depends heavily on the scale of the graphic relative to the garment size. A design that looks great on an XL hoodie might overwhelm a small toddler shirt. By ordering custom DTF transfers by size, you maintain professional proportions across your entire product line.

Proper sizing also ensures that the print sits comfortably within the "safe zones" of the fabric, avoiding seams and pockets. This attention to detail is what separates high-end retail brands from amateur projects. Using exact dimensions ensures that your brand looks consistent and high-quality on every single piece.

If you want to bring your designs for hard surfaces to life in the most efficient and economical way, planning correctly provides a great advantage. With the

Standard Dimensions for Common Items Custom DTF Transfers

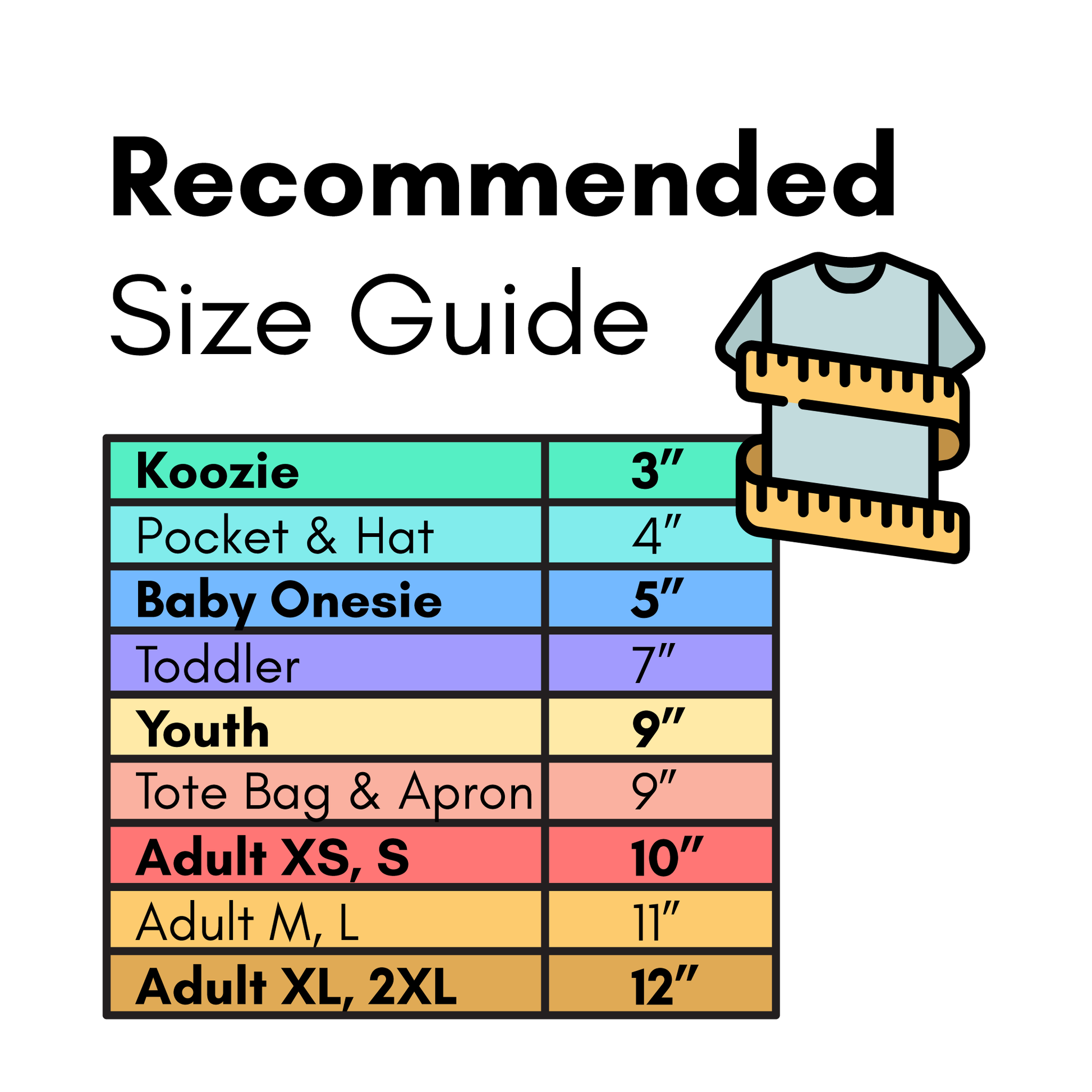

Understanding standard industry sizes can help you make better decisions when placing your orders. For a classic adult "full front" design, a width of 10 to 12 inches is typically the standard. "Left chest" logos, popular for corporate apparel, usually range between 3.5 and 4.5 inches.

If you are branding long sleeves, a narrow 2-by-12-inch strip is often the preferred choice. For children's clothing, you should scale these dimensions down to 6 or 8 inches for a full front. Having a standardized size chart for your brand ensures consistency across every production run and simplifies the ordering process.

The Power of Professional Neck Labels

One of the most overlooked areas for branding is the inside neck of the garment. Small custom DTF transfers—usually around 2 by 2 inches—are perfect for creating professional neck labels. These can include your logo, the garment size, and washing instructions.

Replacing the manufacturer's tag with a soft, printed transfer instantly elevates the perceived value of your shirt. Because these are small, you can fit dozens onto a single gang sheet, making them very affordable. Small details like these create a cohesive and professional brand experience that customers appreciate and recognize.

Optimizing Large-Scale Back Prints

When you want to make a bold statement, a large back print is the way to go. These designs often require the maximum width available on a DTF roll, which is typically 22 inches. However, you must be careful with the height to ensure the design doesn't tuck into the waistband.

A standard large back print is usually 11 to 12 inches wide and up to 14 inches tall. Ordering these specific sizes ensures that your artwork remains the focal point without becoming distorted. Large transfers require steady pressure and heat, so size accuracy is vital for a perfect, professional application.

Using Gang Sheets for Multiple Sizes

If you need several different sizes of the same logo, a gang sheet is your best friend. Instead of ordering individual transfers, you can place various sizes on one continuous roll of film. For example, you can fit front designs, chest logos, and neck labels on a single sheet.

This approach allows you to satisfy the needs of an entire order—from small to extra-large garments—in one go. Online gang sheet builders make it easy to resize and duplicate your artwork to fill the space efficiently. Strategic sizing on a gang sheet is the ultimate way to lower your unit costs and save time.

Measuring Your Garments Correctly

Before you place an order, it is essential to physically measure the "print area" of your specific blanks. Different brands of hoodies and t-shirts have different distances between the collar and the pockets. Use a ruler or alignment tool to find the exact center and the available width.

If you are printing on a pocket tee, measure the pocket specifically to ensure your logo sits perfectly inside the boundaries. Taking these measurements beforehand prevents the frustration of receiving transfers that are slightly too large. Accuracy in measurement leads directly to perfection in the finished product.

Resolution Considerations for Small Sizes

When you scale a design down to a very small size, such as a 1-inch icon, resolution becomes even more important. Fine lines and small text can sometimes "close up" if they are too thin or if the resolution is low.

Ensure your small transfers are designed with a minimum line thickness of 0.02 inches to allow the adhesive to bond properly. If your logo has complex details, you may need to simplify it for smaller applications to maintain clarity. High-resolution files (300 DPI) are mandatory to keep small text readable and crisp across all garment types.

Specialized Sizes for Hats and Accessories

DTF technology isn't just for shirts; it is also perfect for hats, bags, and shoes. Sizing for these accessories is much more restrictive than for apparel. For a standard baseball cap, a transfer should be no taller than 2.25 inches and no wider than 4 inches.

Tote bags offer a larger canvas, but you should still leave a healthy margin from the edges. When ordering for accessories, it is helpful to print a "paper mock-up" first to see how the size looks on a curved surface. Correct sizing ensures that your branding looks intentional and well-designed on any item you sell.

Managing Inventory by Specific Size

As your business grows, you may want to keep a stock of your most popular logos in various sizes. Storing pre-printed transfers is much more space-efficient than storing boxes of pre-printed shirts. You can organize your storage by size, such as "Left Chest 4-inch" or "Full Back 12-inch."

This allows you to fulfill orders instantly as they come in, regardless of what garment the customer chooses. Having a ready-to-press inventory categorized by size makes your workflow incredibly agile. You can respond to customer needs in minutes rather than days, increasing overall efficiency.

Conclusion: Strategic Custom DTF Transfers

In conclusion, ordering Custom DTF Transfers by Size is a fundamental skill for any professional garment decorator. It allows for better aesthetics, lower costs, and a more diverse product range. By understanding standard dimensions and utilizing gang sheets, you can maximize the potential of every print run.

Whether you are focusing on small neck labels or massive back pieces, precision is the key to a retail-ready finish. The flexibility of modern DTF technology means you are no longer limited by your equipment. Start sizing your designs strategically today and watch your brand's professionalism reach new heights.

To stay connected with the latest projects and community updates from DTF Print House, you can visit their various social media channels. Explore the newest printing techniques and inspiring designs on their Instagram and TikTok accounts. For creative ideas and visual inspiration, check out their Pinterest page. Additionally, you can follow the brand on Facebook to receive current announcements and exclusive deals, ensuring you stay informed about all the innovations in the printing world.